When precision thin metal parts are required, chemical millingmight be the way to go. This subtractive manufacturing process differs from other manufacturing techniques in that it does not require complex tooling or cutting tools. It leaves the parts with smooth, burr-free edges, that do not need any further finishing. It differs from chemical etching in that etching is purely decorative, whereas milling is intended to produce the parts’ finished profile.

This is actually a very old process, which has been modernized. Originally, it was used for nothing more than decorative design work on a knight’s sword or armor. But with today’s photo resistantprocess, it has become very effective in producing a wide range of parts. The process requiring very little tooling, only a film mask, which is made directly from a CAD drawing. Parts can either be pierced through with chemical milling or machined partially through to great precision, depending on the designer’s needs. Multiple parts can be machined simultaneously, reducing manufacturing time and the attending costs.

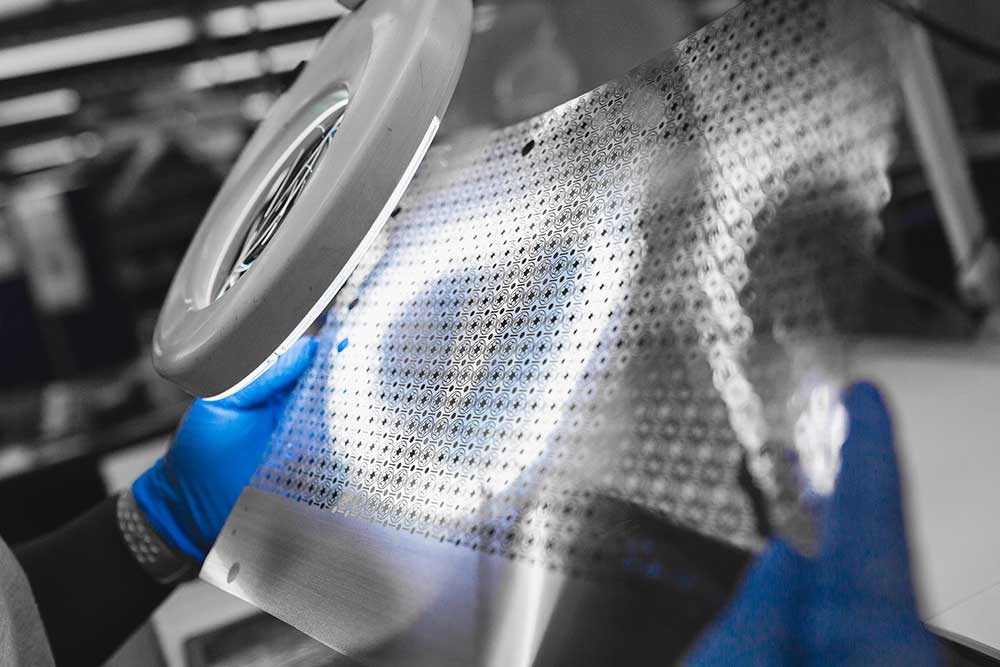

The process begins with material selection. Various metal alloys can be machined chemically, including difficult to work with materials like copper and titanium. The raw sheet metal is cleaned thoroughly to remove lubricants from the manufacturing process. Then a photo resistant masking material is sprayed onto both sides and allowed to dry. This masking material is exposed to light, through the film mask,” setting” the parts of the mask needed. The rest of the mask, which is unexposed is then washed off, making the underlying metal accessible to the etching solution. Masking both sides and etching them simultaneously reduces manufacturing time and the attendant costs.

A variety of different etching solutions are used, based upon the material being chemically milled and the desired results. Parts can either be sprayed with these solutions or dipped, depending on the size of the sheets, the etching solution used and the desired depth. Temperatures and concentrations of these solutions are controlled carefully, as they affect the depth of milling provided.

Once the parts have been milled, excess etching solution is rinsed off and the parts are washed to remove the photo-mask. The now-completed parts can be separated from the sheet and sent on to other machining operations or used without any need for further finishing. Finished parts are clean, smooth and free of burrs.

Chemical milling has been successfully used for the manufacture of aerospace, medical and electronic parts. It is ideal for the production of speaker grilles, electrical contacts, encoder disks, and other small precision parts.