In industrial applications, controlling the flow of a variety of substances requires the use of a flow switch. These highly specialized components work to regulate the flow of a specific product such as gas or oil. They can, however, be used in a wide variety of applications in several industries. There are primarily 4 different types of flow switches and each is created to specifically work in certain industrial environments, but essentially serve the same purpose; to regulate the flow of the product in question. By definition, according to Sciencing, flow is the movement of a substance such as gas or even water within a pipe. The flow switch will control the physical movement through the pipe in a uniform manner by causing the switch to actuate.

- Thermal Flow Switches

A thermal based flow switch may also be referred to as a thermal mass flow meter. Essentially, this instrument detects the heat created on the surface of a flowing liquid and can be used to control virtually any type of liquid used in industrial applications. One of the primary reasons this switch is commonly used for industrial processes according to Wikipedia, is because they have no moving parts and can require very little maintenance and are easy to install.

- Paddle Flow Switches

Paddle switches are very common across many industries and serve a variety of purposes related to controlling a substance’s flow. According to the Minnesota Department of Public Safety, a paddle style switch is also called a vane switch and are commonly used in applications such as sprinkler systems. They are designed with a paddle, or vane, which is inserted into the pipe. Once the flow of water or liquid occurs, it causes the switch to close, and in sprinkler applications this also triggers and alarm. This type of switch can also be used in other scenarios such as HVAC systems and other oil, gas, or water-based systems.

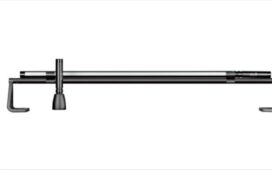

- Shuttle or Piston Flow Switches

These switches are commonly used for heavy equipment and automobiles because they accurately control the flow of smaller amounts of fluids used in machinery. According to Wikipedia, a shuttle or piston switch is generally used in a pneumatic or hydraulic system. It is comprised of three openings and features a freely moving ball which prevents the flow from moving through an opening and forces it through another opening. This design helps prevent back flow and is also a common component in emergency systems and compressors too.

- Piezo Flow Switches

A piezo switch works on the principles of the piezoelectric effect, which states that an A/C electric charge is generated when particular materials are exposed to a certain amount of stress, according to Tech Target’s Whatis.com. Perhaps the most common material used for this type of switch is a quartz crystal. Basically, the switch usually features two metal plates with a crystal in between. When sound waves vibrate the metal plates, it also vibrates the crystal creating a low voltage A/C current which controls the function of the switch. This switch is commonly used in an integrated semiconductor device.

There are many applications in which each switch may be used, but some switches may be used alternately with other types for several different industrial purposes. There may be a few different options to fulfill the need for a flow switch based on purpose it is intended to serve.